Innovation in Renewable Energy Storage!

We offer revolutionary technologies for energy storage and utilization that ensure the future of renewable energy.

Our Visitor

The Invention of the Third Millennium

Transformation of Compressed Air Energy into Compressed Water Energy

Dear Interested Parties,

We have developed a hybrid compressed air storage hydropower plant for the utilization of volatile energy sources. This system enables lossless conversion of compressed air energy into pressurized water energy. Analysis of the energy flows of the hydropneumatic power plant (input and output) showed that the compressed air energy can not only be transferred to pressurized water energy without losses, but that the energy is tripled during reconversion to electricity.

Simultaneous Compressed Air Generation and Recompression

Furthermore, I found that the processes of compressed air generation and reconversion can run simultaneously. This means that the generated compressed air can be immediately converted into pressurized water. The resulting driving water is simultaneously directed through a hydraulic turbine and converted into electrical energy by a generator.

To start the process, a connection to the public grid or, in island operation, a power generator is required. If the plant is to be black-start capable after a blackout, an additional compressed air storage tank is needed.

A Calculation Example as Proof

As proof, here is a calculation example:

Take a standard screw compressor V-Drive T with two-stage compression and variable speed control from Almig, with a rated power of 323.82 kW and, on the output side, a volume flow according to ISO 1217 (Annex C-2009), which guarantees a constant, effective volume of 744.66 liters per second at a constant operating pressure of 13 bar. If this compressed air is simultaneously introduced into a pressure-resistant water tank completely filled with water, the compressed air presses on the water surface. The water is thus converted into driving water (works on the principle of a pressure vessel in a domestic water system).

With a hydraulic turbine (preferably a Pelton turbine, which has very low losses in partial load operation) and generator, the following calculation results:

- Water quantity [l/s]: 744 (same volume as the screw compressor)

- Net head 130 (corresponds to 13 bar – same pressure as the compressor)

- Turbine efficiency [%]: 92

- Generator efficiency [%]: 95

- Turbine output (mech.): 872.38 kW

- Generator output (el.): 828.76 kW

This generates 828.76 kW of electrical energy. If you subtract the 323.82 kW required to drive the compressor, a surplus of 504.94 kW remains.

The output can be significantly increased by returning the compressed air remaining in the empty water tank after a power generation cycle to the compressor, saving about 50% of the energy required for compressed air production.

Calculation:

Generated power minus the energy used to produce the compressed air results in a surplus of

828.76 kW – 323.82 kW = 504.94 kW

- saved half energy costs 323.82 / 2 = +161.91 kW This results in a total surplus of 666.88 kW

You can download the turbine calculation from the internet, e.g., https://www.leimegger.de/Ingenieur/turb_berech.html

With about 666 kW x 8,760 hours (extrapolated to one year), this results in

5,834,160 kWh x 7 ct = €408,391.20 annual revenue

Estimated construction costs of the power plant are about €1.6 million

The payback period is about 4 years!

Explanation of the Surplus

Now all scientists have a problem, because during their studies they were taught that a perpetual motion machine does not exist. My calculations have shown that the surplus does not violate the laws of thermodynamics, but results from the efficient conversion of air, a low-mass medium, into water, a high-mass medium. Due to its low mass, air can be compressed and transported much more easily and with significantly less energy than water.

Here is a calculation example:

A compressor with a rated power of 323.82 kW can generate 744.86 liters per second at a pressure of 13 bar. A water pump with a delivery rate of 744.86 l/s and a pressure of 13 bar requires at least 1,000 kW to achieve the same pressure and volume.

- The laws of gas compression (low mass) apply to the production of compressed air.

- After the transformation of compressed air into driving water, the law of hydropower (high mass) applies to reconversion.

As a reminder from school physics:

- 1 liter of air has a mass of about 1 gram

- 1 liter of water has a mass of about 1,000 grams

A comparison with a steam locomotive shows that compressed air or steam contains more energy potential than often assumed. While a double-piston cylinder of a steam locomotive achieves an efficiency of 99.83%, a gas turbine achieves only 37% due to its design.

In my concept, pressure is used as a source of kinetic energy by converting the pressurized water into driving water, which is then displaced from the water tank and subsequently passed through a turbine to generate electricity. The energy has always been contained in the compressed air; through targeted conversion, it can be utilized much more efficiently.

The fact is that the transformation of compressed air into pressurized water in no way violates the laws of thermodynamics. It is also a fact that electricity is always required to drive the compressor for starting and continuous operation of the power plant, and this also does not violate the laws of thermodynamics.

Summary

Process of Electricity Generation

For continuous power generation, three tanks are needed at the same level. Since the tanks are connected, pipelines in the single- and double-digit meter range can be used, which significantly increases efficiency compared to storage power plants in the mountains with their long pipelines. After starting the compressor, the compressed air is introduced into the first tank filled with water. This creates driving water, which is used to generate electricity via a turbine and generator. The discharged driving water is fed into the second tank. When the water level in the first tank reaches its intended low point, the first power generation cycle ends. The second tank, which in the meantime has been filled with water from the first tank, is hermetically sealed and pressurized with compressed air. The second power generation cycle begins. At the same time, the compressed air from the first tank is returned to the compressor, saving about 50% for compressed air production. After the second power generation cycle, the third cycle follows as before. Then the cycle closes and the first power generation cycle begins again.

I do not need to mention what such an energy multiplication would mean for the global energy industry in the future. Our worldwide fossil energy problem would be virtually solved. This new process holds enormous potential. All environmentally harmful problems would be eliminated and climate protection guaranteed.

The Essential Advantages of the Power Plant

- 100% green electricity, guaranteed emission-free power generation

- The operating media consist of free air and water

- Nonstop operation, 8,760 hours per year

- This power plant is not affected by periods of low renewable generation

- Production costs < 1 ct/kWh

- Decentralized construction of these new power plants relieves the grids

- Service life of the power plant in closed-cycle operation at least 50 years, with reinforced concrete construction even over 100 years

- Clean water extends the service life of the turbines

- This power plant is black-start capable in the event of a blackout

- Sufficient and affordable energy for everyone

- Car and truck traffic can be converted immediately

- All nuclear and steam power plants operated with oil, coal, or gas will be dispensable in the future

- All wind turbines and PV systems can be dismantled, nature conservation can thus be restored

- The climate target will be achieved

- No more demonstrations for environmental and nature protection

Conclusion

This new, hybrid compressed air storage hydropower plant, which does not require topographical elevation, can be installed at any conceivable location on our planet and thus revolutionizes energy generation.

Since this innovative form of energy generation and storage uses machines and technologies already available on the market, the new system can be implemented immediately without long development times and costs.

Three patents for Europe and the USA have already been granted.

Best Regards,

Johann Tauscher

Johann Tauscher

Josef-Kainz-Mayer-Gasse 12

A-1220 Wien

Mobile: +4369917747071

E-Mail: office@greenenergystorage.at

Revolutionäre Technologien Revolutionary Energy Storage Technologies

- Reducing environmental impact

- Storing volatile energy sources

- No topographical limitations

- Optimizing energy efficiency

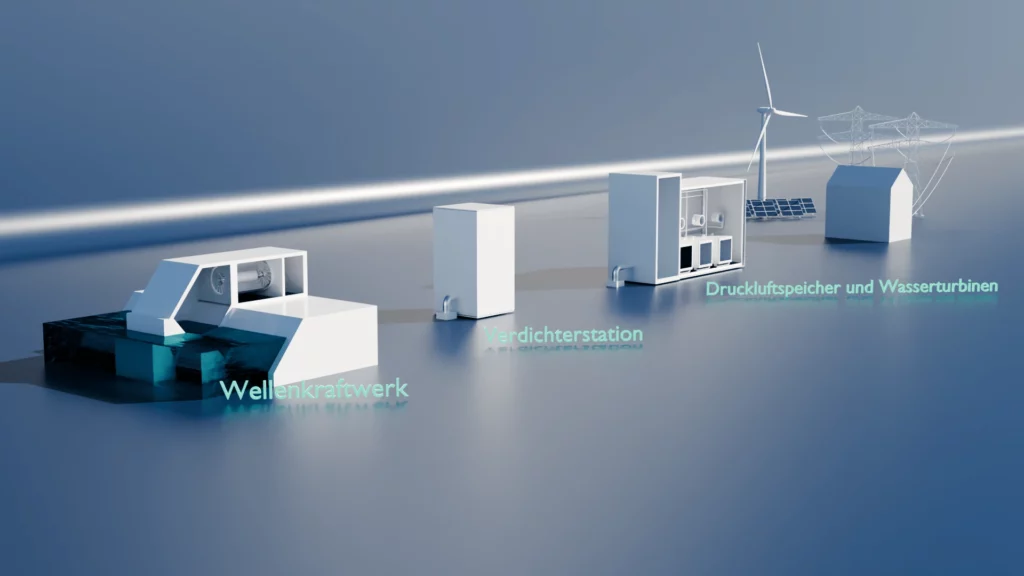

Compressed Air Storage Power Plant

As the energy transition progresses, renewable energy is becoming increasingly in demand. However, it has a downside: it does not guarantee continuous power generation. My hybrid compressed air storage hydropower plant addresses this issue. My concept uses only harmless media such as compressed air and water.

Wave Power Plant

The first wave power plant with a capacity of approximately 300 kW was constructed in Mutriku, Spain in 2011. My concept overcomes the low power issue by not immediately converting the compressed air into electrical energy but storing it in a compressed air storage system. When needed, the compressed air is transformed into pressurized water, which drives a highly efficient water turbine to generate electrical energy and feed it into the grid.

[Learn More]

Johann Tauscher - Pioneer of Innovative Energy Storage Solutions

For over 20 years, I have been dedicated to developing environmentally friendly energy storage solutions. In researching compressed air storage power plants, I found that they invariably use gas expansion turbines.

Experience has shown the disadvantages of gas turbines, as compressed air has almost no mass, leading to unsatisfactory efficiency in energy transmission.

In contrast, using a water turbine instead of a gas turbine achieves an efficiency of over 90%. This is achieved by transforming compressed air into pressurized water.